Weldarc's

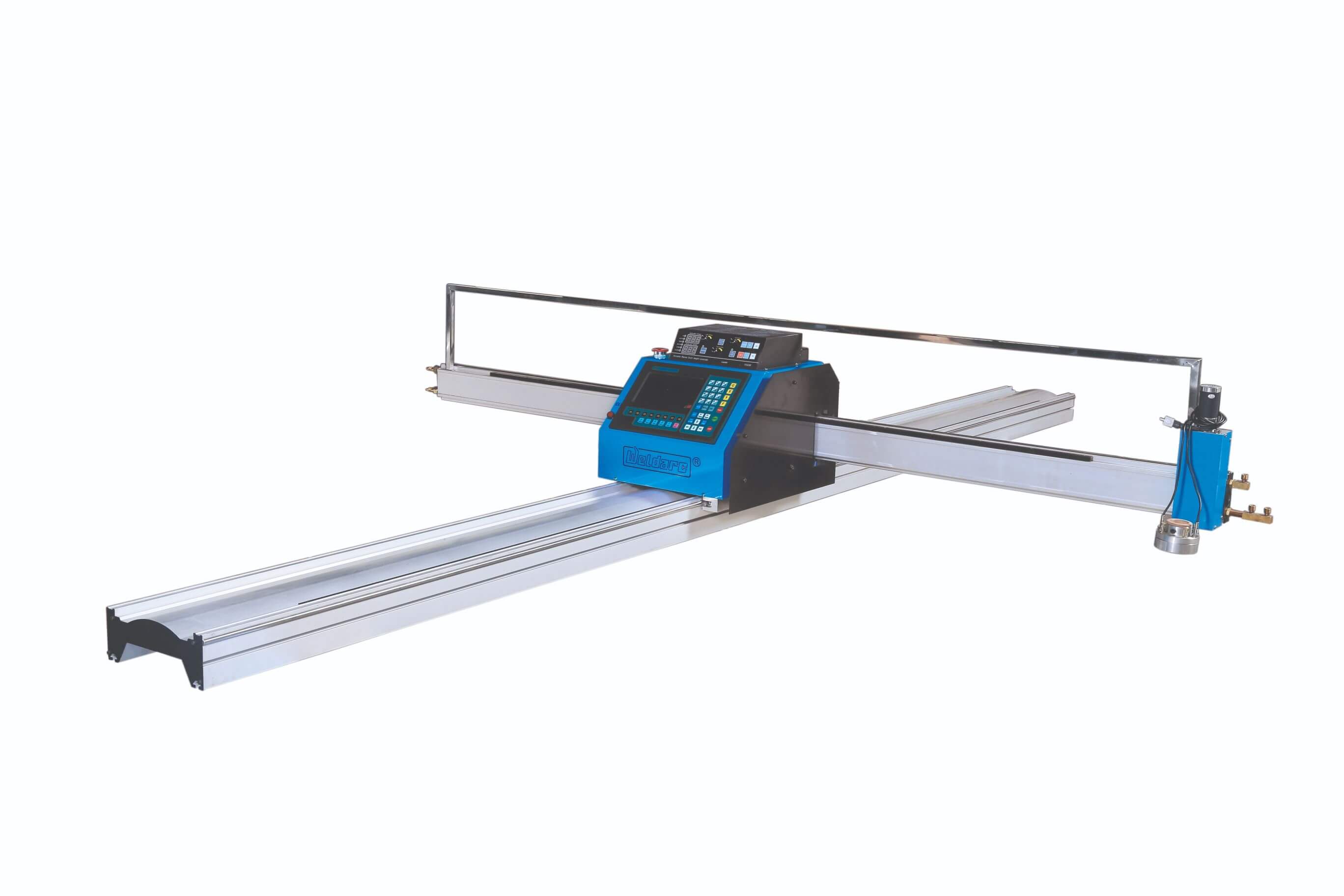

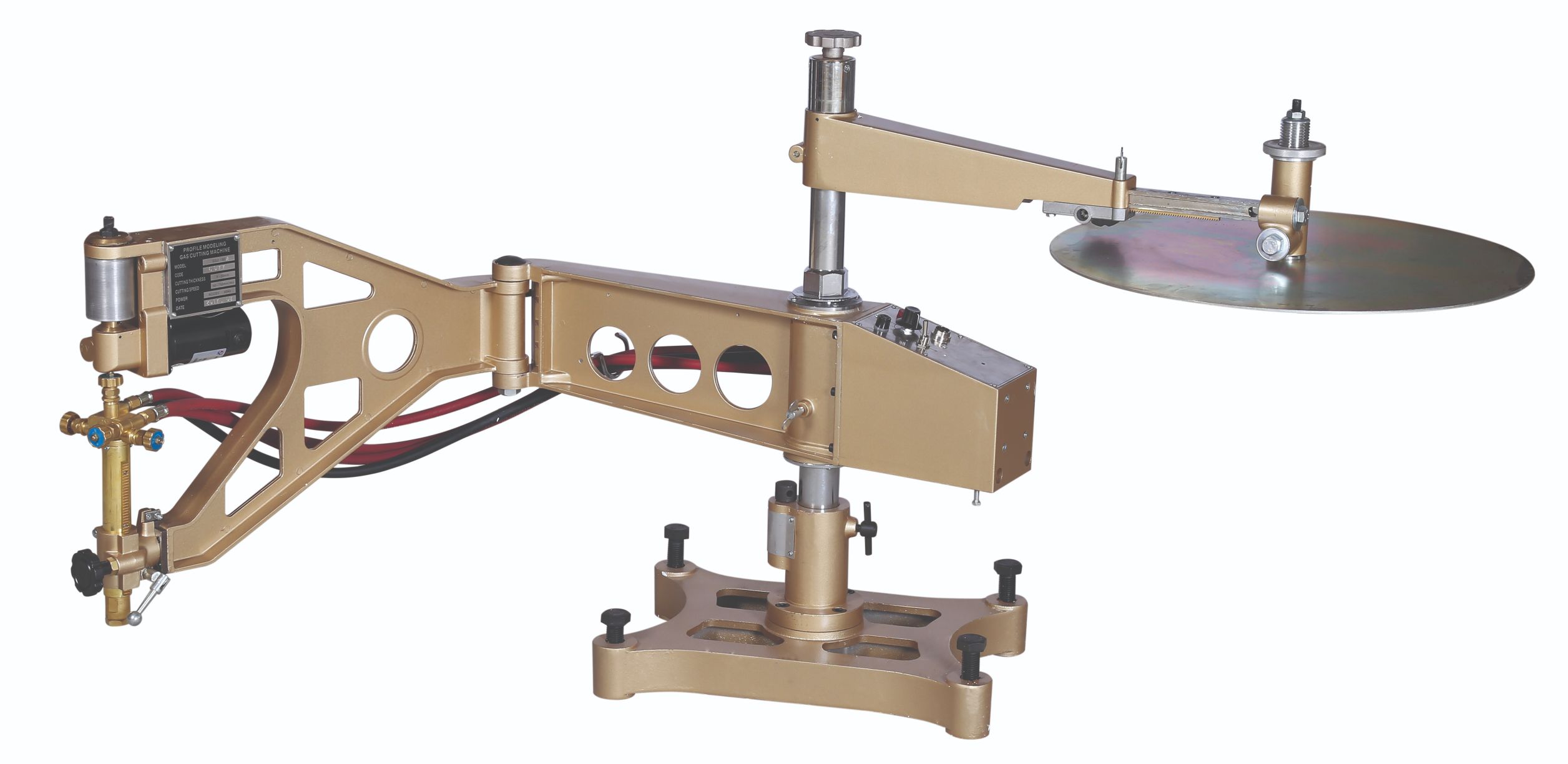

CNC Plasma & Flame Cutting Machine

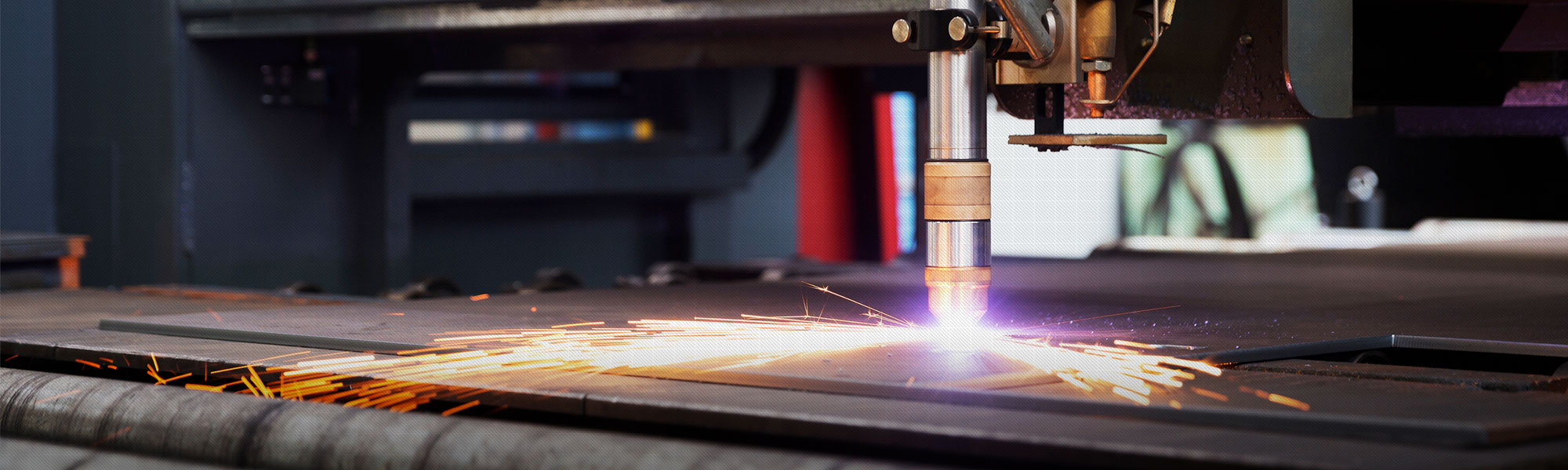

Our Plasma cutting machines offer fast cutting speeds and throughput along with a cheap cost per millimeter of material cut. High-definition systems have virtually or entirely removed the need for secondary procedures on processed parts. Different thicknesses of electrically conductive materials can be processed effectively by plasma cutting machines. Weldarc India offers a variety of plasma tables with Hypertherm sources designed for particular uses or objectives. CNC Plasma & Flame Cutting Machines have been using stably in many Industries like Metal Profile Cutting Industries, Heavy Fabrication Industries, Special Purpose machine Manufacturer, Jigs & Fixtures Manufacturer, Sheet Metal Industries, Agricultural Equipment manufacturing,Auto parts manufacturing Industry.