What is a Fiber Laser Cutting Machine? Understand the Basics

A laser cutter is frequently the best machine for cutting involved forms out of sheet metal or acrylic. High-powered lasers are used in this cutting technology to quickly and accurately cut through materials with amazing accuracy. Not only can laser cutters be used to make clean, precise cuts in a variety of materials, but they can also engrave designs onto surfaces.

However, not all laser cutters are the same. Some feature stronger lasers, allowing them to work with thicker materials or make deeper cuts. Others may include more modern features, such as auto-feeders or dual-laser capabilities, which can boost the speed and efficiency with which your projects can be processed.

Fiber laser cutting machines, a variant of CNC laser cutter, are a popular option. This article will go through the fundamentals of fiber laser cutting machines and how they operate.

Table of Contents

• What is a Fiber Laser Cutting Machine?

• Fiber Laser Cutting Machine Benefits

• Fiber Laser Cutting Machine Drawbacks

• Silver Considerations

What is a Fiber Laser Cutting Machine and How do Fiber Lasers Work?

A fiber laser cutter is, at its core, a highly customised tool that uses laser technology to manipulate a range of materials. This sort of devices makes precise, high-quality cuts in a variety of materials.

The fiber laser cutting machine's main component is the fiber laser itself, which produces a highly focused beam of light capable of easily cutting through even the toughest materials.

While the basic concepts driving these cutting machines are similar to those employed in other traditional laser cutters, the key distinction is in how energy is delivered and focused onto a workpiece.

Let's go through the fundamentals of laser operation. A laser is made up of three primary components:

- A medium of gain

- Pumping optical energy

- Mirrors

The medium for growth is the material in which photons are produced and amplified, whereas pumping creates electrical energy, which is converted into photons within the medium. Finally, the mirrors reflect light over and over again, generating a focused beam of light known as a laser beam.

This method is based on the exacting control of electromagnetic wavelengths, which enables laser beams to convey data with extraordinary precision and efficiency.

A fiber laser cutter, on the other hand, comprises a series of optical cables included of small strands of fiber that transfer light waves straight into the material being worked on. This feature enables for more precision and more focused heat concentration, resulting in cleaner cuts and stronger material bonding.

Other key components of this machine include the software that runs it and the elements that guide and support the material being cut.

Furthermore, fiber lasers may be utilised with a wide range of cutting heads of various shapes and sizes, allowing them to be tailored to individual demands and applications. Overall, fiber lasers are a cutting-edge instrument for cutting and manipulating all types of materials with unsurpassed speed and accuracy.

Fiber Laser Cutting Machine Benefits

Fiber laser cutting has several advantages over conventional cutting processes.

Precise, rapid, and high-quality cutting: The fiber laser cutting machine creates precise and clean cuts with little to no distortion, making it an excellent choice for a wide range of materials.

Increased efficiency: The fiber laser machine's faster cutting speed than previous methods allows you to finish more work in less time.

Reduced downtime: Because fiber lasers are significantly less prone to failure and require very little maintenance, your machines will be up and running more frequently.

Versatility: The fiber laser's capacity to cut through a wide range of materials makes it an ideal instrument for any work.

Cross Fiber Laser Cutting Machine Drawbacks There are a few potential downsides of fiber laser cutting machines:

- Power consumption: One of the most significant downsides of this cutting technology is its high energy consumption and reliance on specific types of lasers, which can be costly to maintain.

- Parts are often more expensive in fiber laser cutters than in other forms of cutting equipment.

- Workers who come into contact with this beam may suffer burns or other damage.

- Material selection: Fiber lasers may not be suited for all metals, including silver.

Silver Considerations:

When working with materials such as silver, it is critical to pay close attention to their specific qualities. Silver, for example, has a relatively high melting point and is susceptible to heat warping during laser-cutting processes.

Because of this feature, machine shops must frequently utilise specialised equipment and techniques to effectively produce components from silver. A heat sink bracket is a frequent remedy for this problem.

The heat sink functions as a buffer between the laser and the workpiece, evenly spreading any extra heat and preventing it from causing excessive warping or damage to the workpiece. Finally, using a bracket as a heat sink in fiber laser cutting processes allows producers more material choice while also assuring that they can obtain ideal results every time.

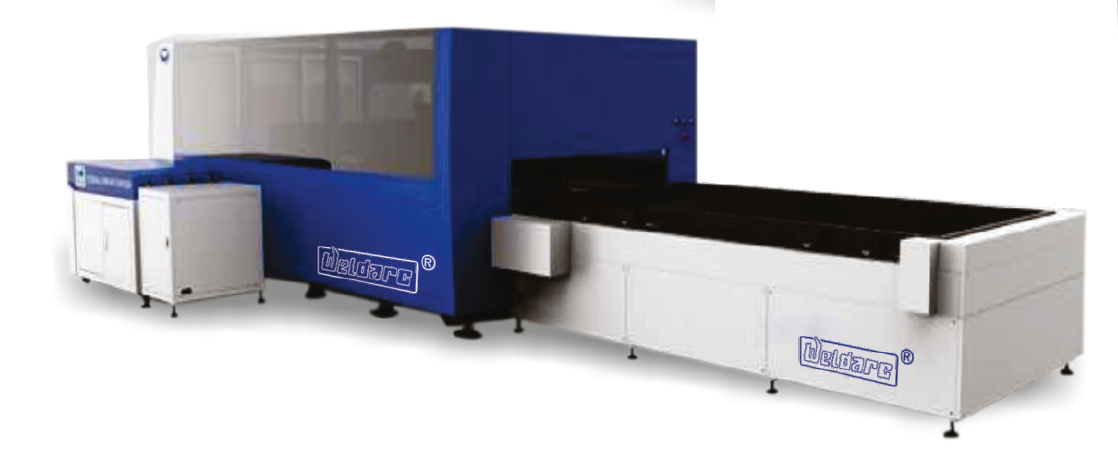

Laser Precision for the Most Demanding Projects With Weldarc

If you're seeking for a production partner who can help you cut expenses while keeping high quality standards, look no further than Weldarc. Our cutting services are second to none, allowing us to offer high-quality products fast and efficiently.